U.S.A. Drives has a diverse product capabilities serving numerous markets and companies around the globe. We pride ourselves on being able to efficiently and economically supply:

-

Standard and Engineered Products

-

Low and High Volume production

-

The Smallest and Largest Molded Endless belts in the Industry

Industries Served: Companies Served:

Food Processing Food Packaging Northrop Grumman

Corrugated Printing Machinery Medical Devices Otis

Small Office Electronics Personal Mobility Pitney Bowes

Bottling Machinery Sports Equipment Hewlett Packard

Robotic Track Belts ATM/Banking Siemens

Cosmetics/Personal Hygiene Tobacco Machinery Bridgestone

Textiles Automated Packaging M&M Mars

This belt feeds plastic syrup bottles into an up-right position and then conveys it through the filling operation. The compression of the soft conveying side is necessary because the bottle, with its irregular contours, rotates 160 degrees when being up-righted, yet the belt must retain enough contact and friction to convey the bottle through the filling station. The "V" Center on the pulley side of the belt is to maintain tracking because flanges on the outside of the pulleys cannot be used.

These belts are used on equipment that packages potato chips and other related snack items. This popular dual durometer packaging belt has a soft, Shore A40 cover (to assist in pulling the bag into the operation) combined with a standard Shore A80 tooth-side for reliable positive drive. Urethane is an appropriate choice for this application in that it will last longer and work better on a wide range of packaging materials.

This belt is used in packaging women’s personal hygiene products (tampons). The belt is extremely “special” in that it has three separate durometers throughout the belt. The first durometer is a Shore A80 formulation with a self-lubricating agent, used in the belt teeth to reduce noise. The belt body incorporates high-modulus polyester with a Shore A83 urethane formula. The final durometer, used to create the backside lugs, is a Shore A96 to Shore D65 material.

This is a metric pitched timing belt used to convey bite-sized candy bars. Being that the belt comes in contact with food, the belt must be made with an FDA-approved urethane. The formulation calls for a standard Shore A80 urethane and Kevlar cord construction.

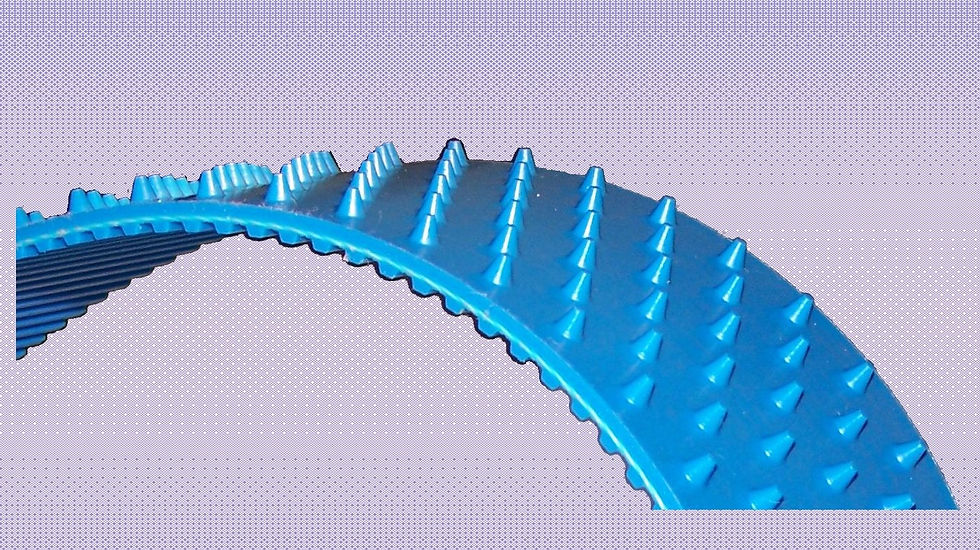

Nubbed belts with metal formulated in for magnetic screening to remove any nubs that may fall off while transporting meat products

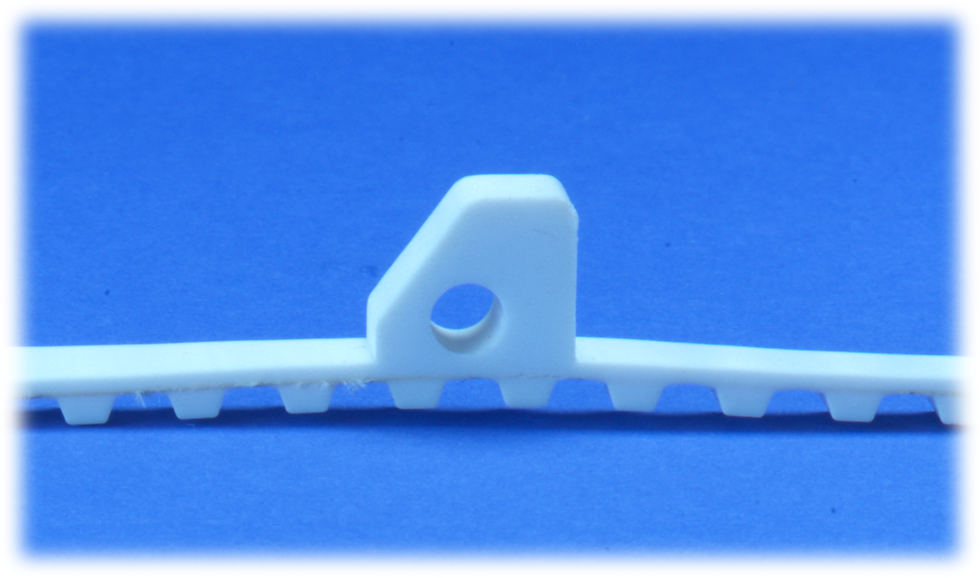

Transport Belting, teeth centering for use with no flange pulleys, lugs shaped to engage slats of conveyors.

Vectran reinforced belting, which complies with FDA/USDA regulations, encapsulated to prevent bacterial growth on edges of the belting.

Anti-Static Urethane Formulation A major paper manufacturer uses this belt to “flip” pieces of paper during the production process and before packaging, getting rid of unwanted static electricity. The belt is made with a standard Shore A80 formulation and a Kevlar cord construction, with an anti-static agent added. The belt must be flexible, however the backside fins also have a rigidity that helps move the paper effectively.

Roller is used on a semi-conductor test machine. The parts need to be tested at both temperature extremes. Most rollers previous to the U.S.A. Drives roller would freeze and harden to A-95, causing damage to the computer chips. The U.S.A. Drives’ roller hardens only 15 points. The roller must also be anti-static so that electrical discharges will not destroy the product being tested.